The mechanical spindle is one of the most important components for precision machines. They are so important that they let machines get their specific jobs done, and they become significantly important when it is about manufacturing products in a factory. This article will delve into the details of the role automatic mechanical spindles play in product fabrication, along with enhancing the operational aspects of machines across industries.

What Are Mechanical Spindles?

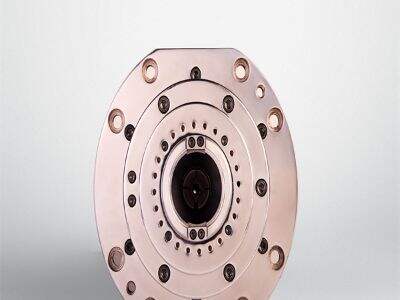

As the title indicates, they are used in machines that cut and shape materials. These metal lathe spindle tools are intended to help in the rotation of tools and materials, which is very important in making accurate cuts. Mechanical spindles can be found in many machines such as Lathes, milling machines, and grinders. Such machines are employed in industries as varied as making airplanes to automobiles to medical appliances. Mechanical spindles make the development of the intricate forms and parts needed for various sectors much easier.

What Does Mechanical Spindles Do?

Mechanical spindles hold and turn cutting tools and materials together to assist in the creation of products. They bearing sleeve lock nut are composed of durable materials, such as steel, which allows them to withstand a lot of stress. The spindle, which contains a motor inside it to rotate it over. The spinning of the spindle also causes the tool unit to swing around. It is this spinning motion that allows the cutting tool to cut the material very precisely to create the desired shape and finish of the parts.

Importance of Mechanical Spindles

Modern factories rely heavily on mechanical spindles. They use machines to make precise cuts, a need that exists in numerous industries. For example, manufacturing precise parts in aerospace is a matter of safety and performance. Mechatronic spindle types can also be applied to machine more exotic thin-walled brittle materials, like titanium, or even hardened steel because they tend to use other special machines in order to be machined properly. The ball screw bearing support spindles can be sped up to high speeds, helping factories be able to operate far more efficiently and quickly, therefore improving productivity and efficiency.

How Do Mechanical Spindles Help Machines?

For example, mechanical spindles are highly used for the purpose of achieving high accuracy and efficiency in machines. These help machines in precise cuts, which forms a fundamental component for many jobs. Mechanical spindles can create accurate parts for electronic appliances, vehicles, and other similar devices. This is a flexible device that can be used for various machines; therefore, they become practical instruments in the production line. This means that manufacturers can use mechanical spindles to accomplish many jobs.

Mechanical Spindles: Design and Care

Mechanical spindles are built for accuracy and durability. They are made of high-quality materials that can withstand a lot of pressure and wear over time. They need to be kept in top condition, so they need maintenance and consultations. That means checking them for proper spinning and replacing any worn parts. Maintenance of mechanical spindles is one of the significant aspects that will help to preserve the performance of machines and ensure quality products are produced.

In Summary

Modern manufacturing depends highly on mechanical spindles. They guide machines to make accurate cuts, which is crucial in many different jobs. In most factories, these spindles will be applied in various machines, making them promissory tools for any factory. For manufacturing, companies such as SWT strive towards supplying quality mechanical spindles and other high-precision tools to enhance the production methods. This can be done in machines by applying efficient mechanical spindles.

Mechanical spindles are one of the most significant components for precision machines. They are so vital that let machines get their specific jobs done, and they become significantly vital when it is about producing products in a factory. This article is going to provide insight into how automatic mechanical spindles have played a part in product manufacturing, plus the improvement in operational machinery activities across industries.

What are Mechanical Spindles?

As the name itself indicates, they are used in machines that cut and shape materials. These metal lathe spindle tools are meant to assist in rotating tools and materials, which is vital when creating accurate cuts. Mechanical spindles can be found in many machines including Lathes, milling machines, and grinders. These machines are used in industries ranging from building airplanes to cars to medical devices. Mechanical spindles make it much easier to create the complicated shapes and parts needed in various industries.

What Is the Function of Mechanical Spindles?

Mechanical spindles hold and turn cutting tools and materials together to help create products. They bearing sleeve lock nut are made out of strong materials, such as steel, which makes them able to endure great amounts of stress. The spindle, which has a motor inside it to spin it over. The spindle can also make the tool unit swing around. The spinning motion makes it easy for the cutting tool to cut the material very precisely in the desired shape and finish of the parts.

Importance of Mechanical Spindles

They use mechanical spindles for their work in modern factories. The use of machines for accuracy in cuts is a requirement for many industries. For instance, in the aerospace industry, producing the right parts is crucial for safety and performance. Mechanical spindle types can also be used to machine more exotic thin-walled brittle materials like titanium or hardened steel as they often use specialized machines to be machined correctly. The ball screw bearing support spindles can spin at high speeds allowing factories to work more effectively and rapidly thereby improving productivity and efficiency.

How Do Mechanical Spindles Help Machineries?

Mechanical spindles are highly used in machines to ensure high precision and efficiency. This helps machines make accurate cuts, a basic requirement for many types of jobs. Mechanical spindles help in creating precise parts for electronic devices, vehicles, and other kinds of high-tech devices. They are versatile and can be used in a wide variety of machines, making them practical instruments in the manufacturing process. This versatility enables manufacturers to use mechanical spindles for many different tasks.

Mechanical Spindles: Design and Care

Mechanical spindles are designed to be accurate and durable. They are made of high-quality materials that can withstand a lot of pressure and wear over time. They need to be kept in top condition, so they need maintenance and consultations. That means checking them for proper spinning and replacing any worn parts. Maintenance of mechanical spindles is one of the significant aspects that will help to preserve the performance of machines and ensure quality products are produced.

Summary

Mechanical spindles are essential for today's industries. They perform sharp cuts directed by machines. These are what most work involves. Any factory should expect to see various machines at most factories. Hence, they have much hope in these mechanical spindles for any of the factories. Companies such as SWT work toward offering quality mechanical spindles and other highly accurate tools towards more efficient manufacturing processes. It is possible within the machines and their use in more efficient mechanical spindles.