SWT

Introducing the SWT/R Series Precision Lock Round Nuts for Machine, the innovation is latest from the popular brand name, SWT. Meant to provide performance is efficiency superior these peanuts are perfect for a wide range of device applications.

Built for accuracy and durability, the SWT/R Series Precision Lock Round Nuts are manufactured from high-grade materials that ensure functionality that is durable. Built to withstand probably the conditions that are working are toughest, these peanuts are ideal for used in hefty equipment and gear.

Among the many standout top features of these nuts is their power to supply a protected and securing system that is stable. The precision teeth from the nut supply a snug and fit that is prevent is secure and loosening during operations. With such locking is reliable, you are able to be confident that your particular equipment is secure and protected at all times.

The SWT/R Series Precision Lock Round Nuts for Machine can also be incredibly very easy to set up, making them an option this is certainly DIY that is fantastic and specialists alike. The peanuts have a smooth, circular area that delivers a suitable hold, enabling simplicity of good use and installation is certainly quick.

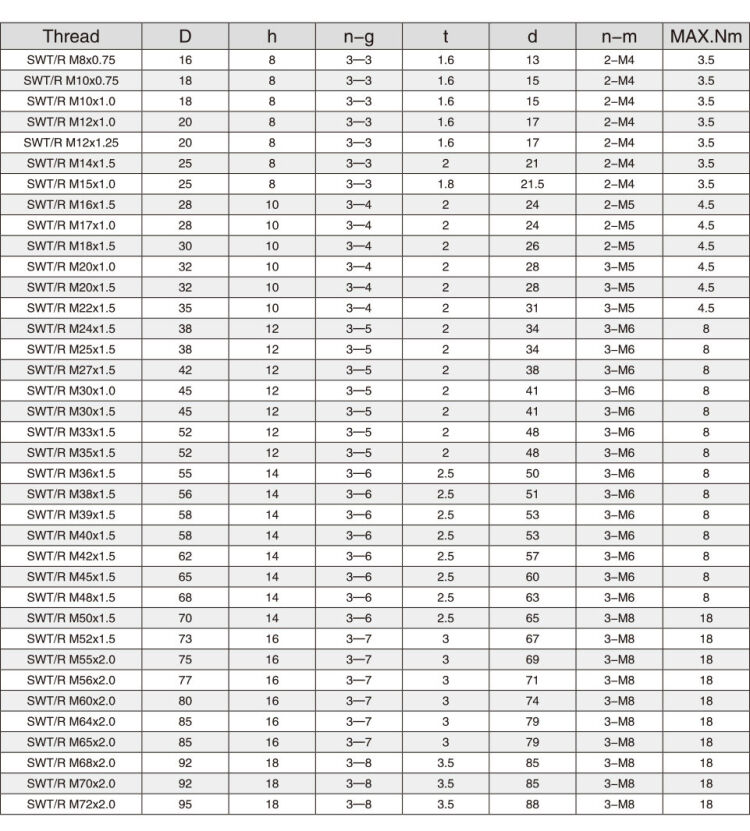

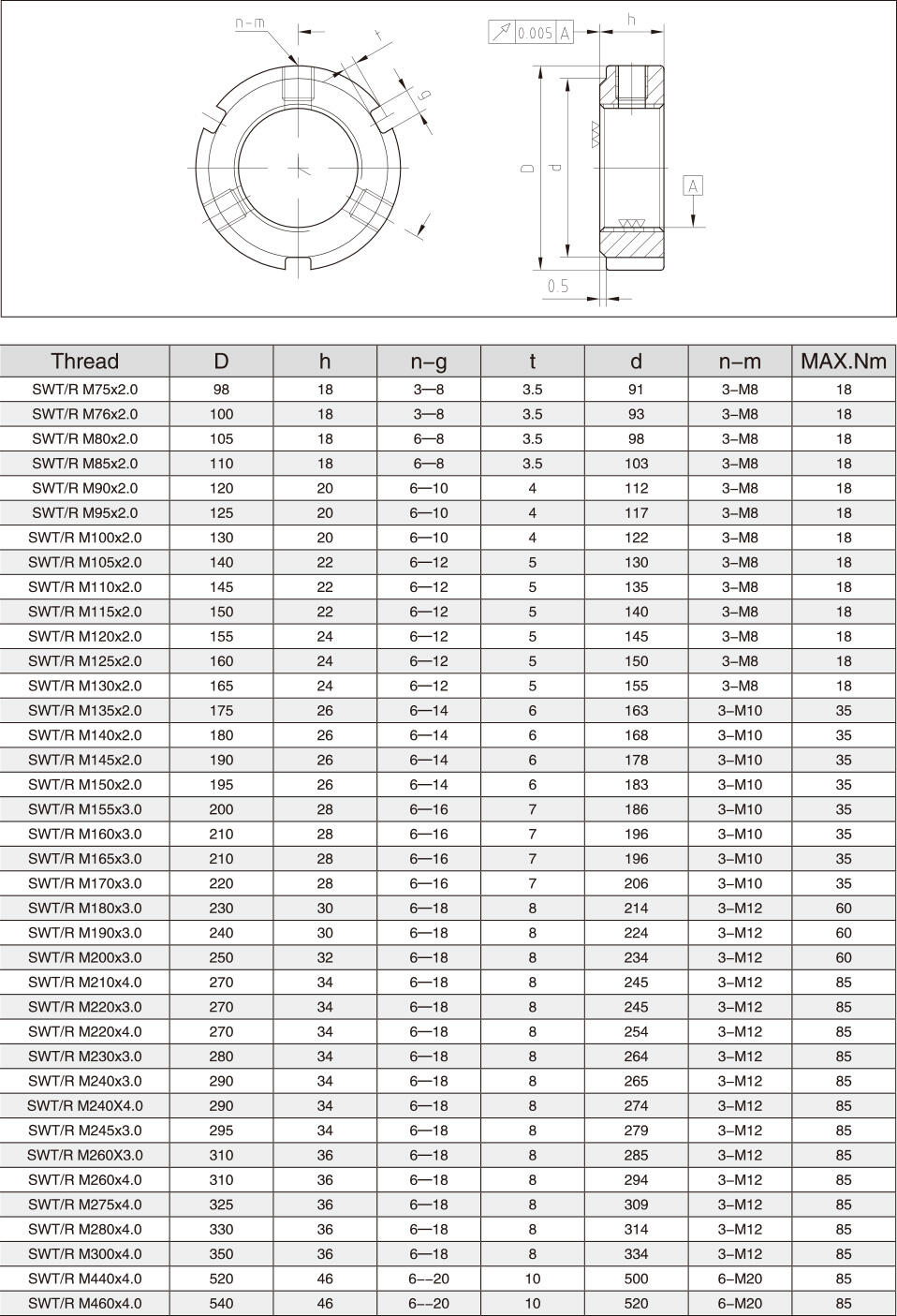

One of several simple items that sets the SWT/R Series Precision Lock Round Nuts apart from other peanuts is their flexibility. These nuts may be present in many different sizes and can fit a range of devices, making them and choice is certainly perfect companies with diverse machinery requirements. You covered whether you're trying to find nuts to suit small or large machines, the SWT/R Series Precision Lock Round Nuts have.

The SWT/R Series locknuts employ 3-way radial locking. It is comparatively thinner and is especially suitable for installation that is restricted by space limitation.

Material: 42CrMo, 40Cr, #45 steel

Hardness: HRC28-32

Thread precision: ISO4H

Run out: 0.005mm

Established in 2011, Jiangsu Swift Machinery Technology Co., Ltd focuses on providing solutions for precision components for numerical control machine tools. The company has passed TS16949 and ISO9001 -2008 and listed on National Equities Exchange and Quotations (also known as New Third Board) in December, 2016.

SWIFT has the modernized temperature-controlled machining and assembly workshops and has imported top-leveled SWISS STUDER universal grinding machine, Japanese

OKAMOTO Surface Grinder, Korean DOOSAN turning center and machining center, German ZEISS CMM, German MAHR contour and form measuring units. From material to the finished products, all the production procedures are done within SWIFT factory which ensures instant delivery, super quality and competitive cost of SWIFT products.

Furthermore, with the continuous efforts of the Research and Developing team, updated technology and ideas are applied to optimize and improve the existing products and to make our products more productive and efficient.

Products series:

Machine tool spindle: BT30/40/50, HSK-A63, HSK-A100 Belt-drive, Direct-drive, Motor Spindle, Spindle for Lathe, etc.

Precision lock nut: M8~M200 (8 series: R/F/K/A/FA/AN/RN/N) Grade: JIS1

Support unit: SWT WBK17~WBK40 (DF, DFF, DFF), EF/EK/AF/AK/FF/FK/BF/BK

Powder Metallurgy products: 27 series (can be applied to a variety of guideways)

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy