SWT is simply a brand this is certainly leading produces high-quality fasteners for the range of industries. Their product that is latest, the SWIFT-SWT/N Export Lock Nuts And Lock Washers, was created to offer an additional layer of protection for fasteners in industrial settings.

Among the list of primary benefits of the SWIFT-SWT/N Export Lock Nuts And Lock Washers may be the proven fact that they assist in preventing bolts and screws from loosening as a result of vibration or other facets that can easily be outside. The lock peanuts and washers interact to produce a safe lock up up against the fastener, which helps to help keep everything constantly in place and avoid downtime this is certainly costly.

Another advantage when it comes to SWIFT-SWT/N Export Lock Nuts And Lock Washers is the fact that these are typically made to withstand the rigors of industrial environments. Produced from top-notch materials, these peanuts and washers can tolerate conditions that are extreme harsh chemicals, and loads being hefty. This system is therefore appropriate use within a variety this is certainly wide of these as production, automotive, aerospace, and agriculture.

One of many key top features of the SWIFT-SWT/N Export Lock Nuts And Lock Washers may be the known fact that they truly are quite simple to set up. The lock nuts make use of a wrench that is standard which means that no tools that are unique required. Furthermore, the washers are reusable, which decreases the requirement for replacement and saves time and money.

The SWIFT-SWT/N Export Lock Nuts And Lock Washers are also available in a selection of sizes and materials to accommodate applications and that can be various. For a small DIY project and even a large commercial plant, there is certainly a size and material whether you need them for you personally.

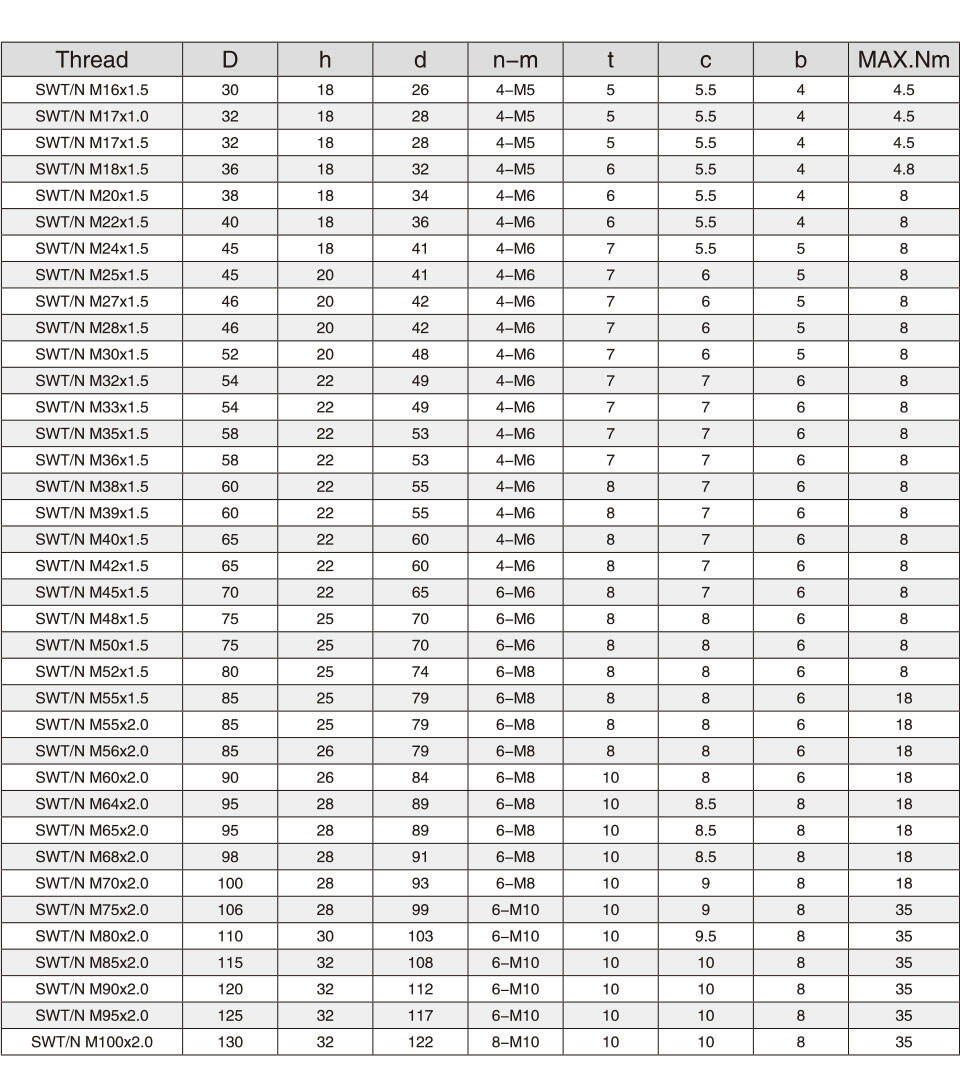

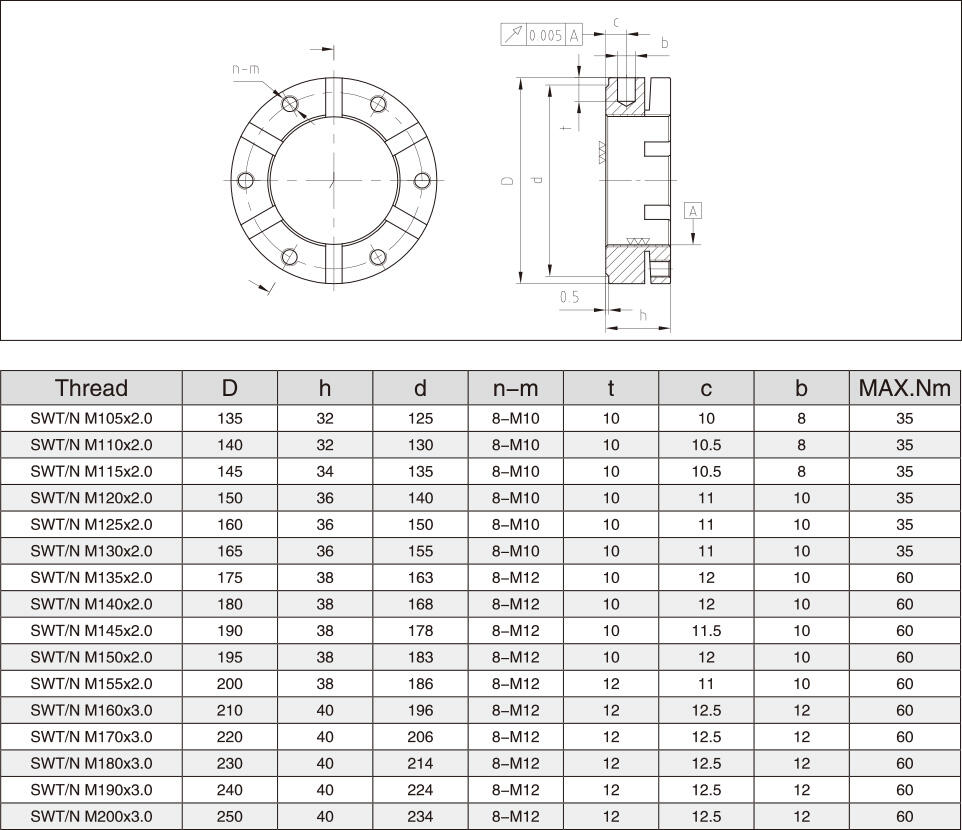

The SWT/N Series locknuts are locked by applying 4-6 high-strength flat screw to support the end surface, with the steel's elasticity, the thread is deformed to be locked. The external dimenson is close to and can be interchangeable with F type nuts. N type nuts are applicable to installation where the nuts could be easily loosened and space is limited. The locking capacity is 2 times bigger than that of F-type nuts.

Material:42CrMo, 40Cr, #45 steel

Hardness: HRC28-32

Thread precision:ISO4H

Run out: 0.005mm

Established in 2011, Jiangsu Swift Machinery Technology Co., Ltd focuses on providing solutions for precision components for numerical control machine tools.The company

has passed TS16949 and ISO9001 -2008 and listed on National Equities Exchange and Quotations (also known as New Third Board) in December, 2016.

SWIFT has the modernized temperature-controlled machining and assembly workshops and has imported top-leveled SWISS STUDER universal grinding machine, Japanese

OKAMOTO Surface Grinder, Korean DOOSAN turning center and machining center, German ZEISS CMM, German MAHR contour and form measuring units. From material to

the finished products, all the production procedures are done within SWIFT factory which ensures instant delivery, super quality and competitive cost of SWIFT products.

Furthermore, with the continuous efforts of the Research and Developing team, updated technology and ideas are applied to optimize and improve the existing products and

to make our products more productive and efficient.

Products series:

Machine tool spindle:BT30/40/50,HSK-A63,HSK-A100 Belt-drive, Direct-drive, Motor Spindle, Spindle for Lathe,etc

Precision lock nut: M8~M200(8 series: R/F/K/A/FA/AN/RN/N) Grade: JIS1

Support unit:SWT WBK17~WBK40(DF,DFF,DFF), EF/EK/AF/AK/FF/FK/BF/BK

Powder Metallurgy products: 27 series (can be applied to a variety of guideways)

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy