The SWIFT-SWT/N Precision Axial Lock Nut is just a durable and product which is reliable to improve the longevity and performance of equipment. The SWT brand is actually a title this is certainly trusted the industry and contains been quality that is producing and products for quite some time.

The axial lock nut is certainly an component that is vital any device that will require placement that is precise alignment. It helps to bearings that are secure other components that are going preventing them from moving or becoming misaligned. This, in turn, decreases friction, vibration, and wear and tear on machinery, leading to increased upkeep and efficiency that is paid down.

The SWIFT-SWT/N Precision Axial Lock Nut is constructed of top-notch materials, including metal that is brass that is hardened. This may make it resistant to corrosion, use, and damage from extreme temperatures and conditions that are harsh are working. The style comes with a feature that is double-locking which ensures safety that is maximum stability, even yet in high-speed applications.

Installing the SWIFT-SWT/N Precision Axial Lock Nut is not difficult and quick, needing tools that are just basic training this is certainly minimal. The product can be highly customizable also, by having a array of sizes and thread patterns offered to fit applications which are certain. Which means that companies can select lock this is certainly perfect for their equipment, ensuring performance that is optimal longevity.

The SWIFT-SWT/N Precision Axial Lock Nut works for use within a variety this is certainly wide of applications, including automotive, aerospace, mining, and more. Its flexibility and durability make it an choice that is perfect organizations trying to enhance the performance and reliability of these equipment without incurring high expenses.

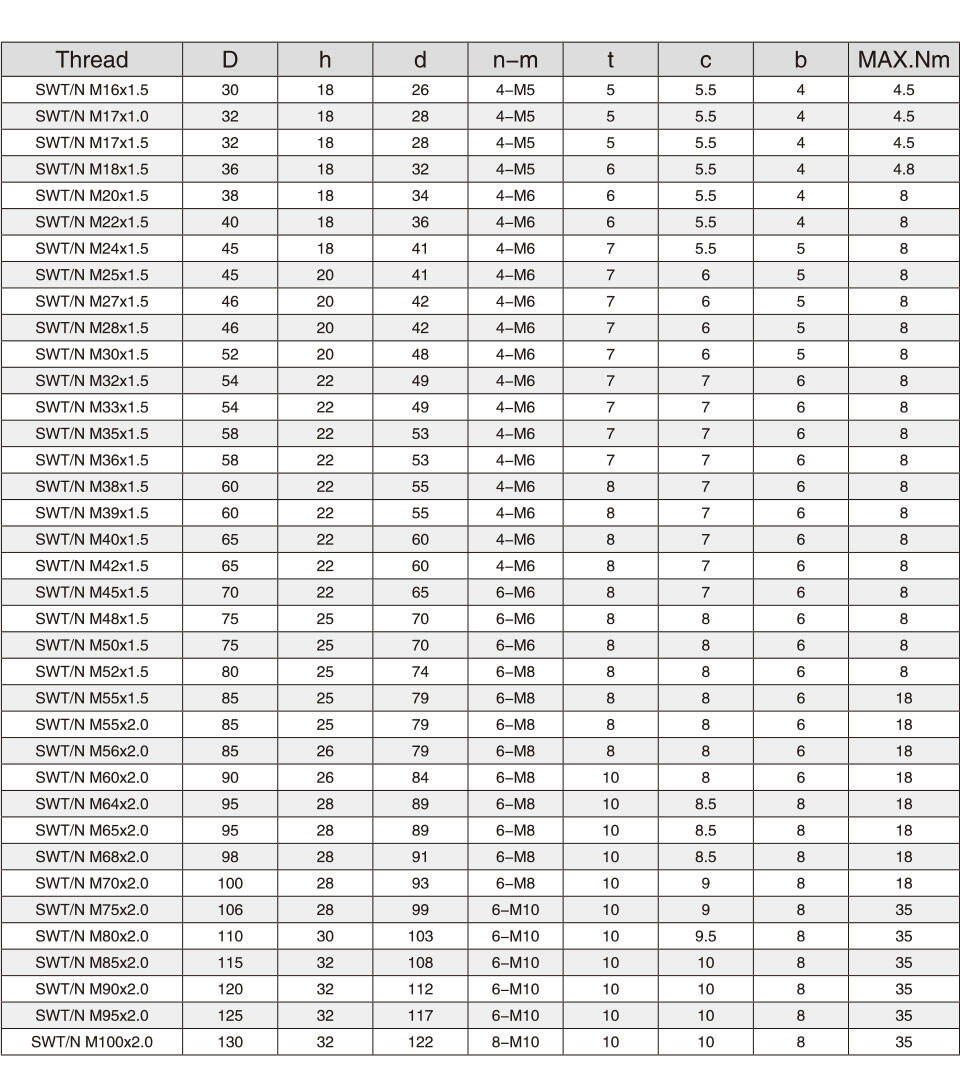

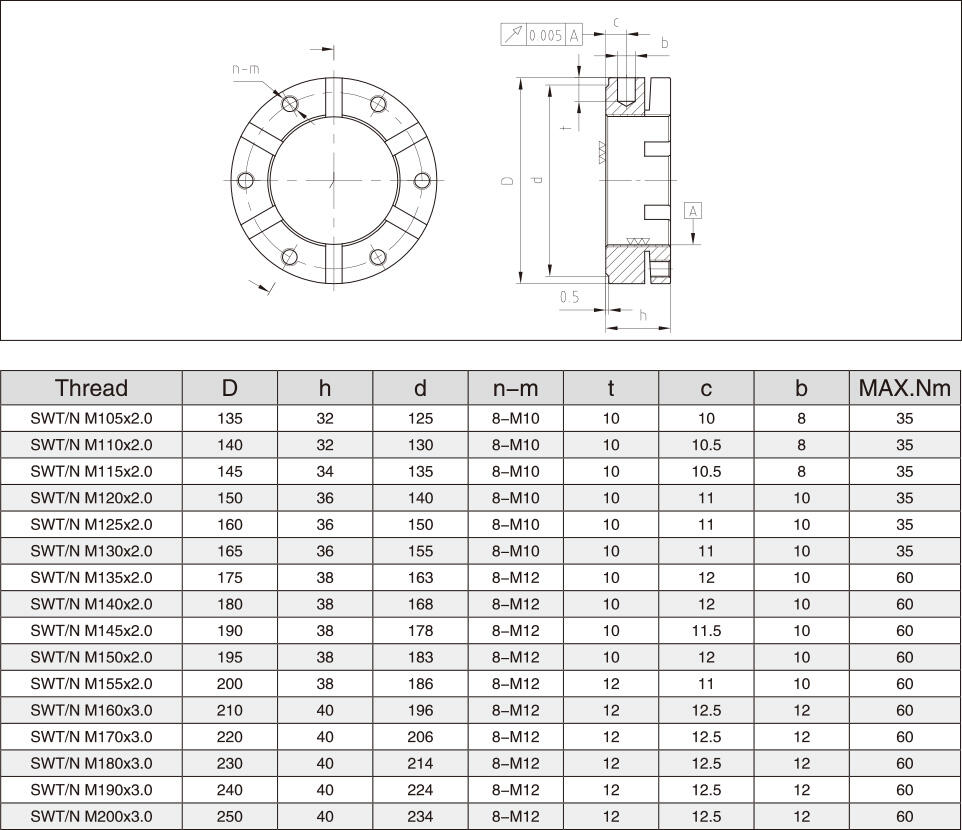

The SWT/N Series locknuts are locked by applying 4-6 high-strength flat screw to support the end surface, with the steel's elasticity, the thread is deformed to be locked. The external dimenson is close to and can be interchangeable with F type nuts. N type nuts are applicable to installation where the nuts could be easily loosened and space is limited. The locking capacity is 2 times bigger than that of F-type nuts.

Material:42CrMo, 40Cr, #45 steel

Hardness: HRC28-32

Thread precision:ISO4H

Run out: 0.005mm

Established in 2011, Jiangsu Swift Machinery Technology Co., Ltd focuses on providing solutions for precision components for numerical control machine tools.The company

has passed TS16949 and ISO9001 -2008 and listed on National Equities Exchange and Quotations (also known as New Third Board) in December, 2016.

SWIFT has the modernized temperature-controlled machining and assembly workshops and has imported top-leveled SWISS STUDER universal grinding machine, Japanese

OKAMOTO Surface Grinder, Korean DOOSAN turning center and machining center, German ZEISS CMM, German MAHR contour and form measuring units. From material to

the finished products, all the production procedures are done within SWIFT factory which ensures instant delivery, super quality and competitive cost of SWIFT products.

Furthermore, with the continuous efforts of the Research and Developing team, updated technology and ideas are applied to optimize and improve the existing products and

to make our products more productive and efficient.

Products series:

Machine tool spindle:BT30/40/50,HSK-A63,HSK-A100 Belt-drive, Direct-drive, Motor Spindle, Spindle for Lathe,etc

Precision lock nut: M8~M200(8 series: R/F/K/A/FA/AN/RN/N) Grade: JIS1

Support unit:SWT WBK17~WBK40(DF,DFF,DFF), EF/EK/AF/AK/FF/FK/BF/BK

Powder Metallurgy products: 27 series (can be applied to a variety of guideways)

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy